Page Information

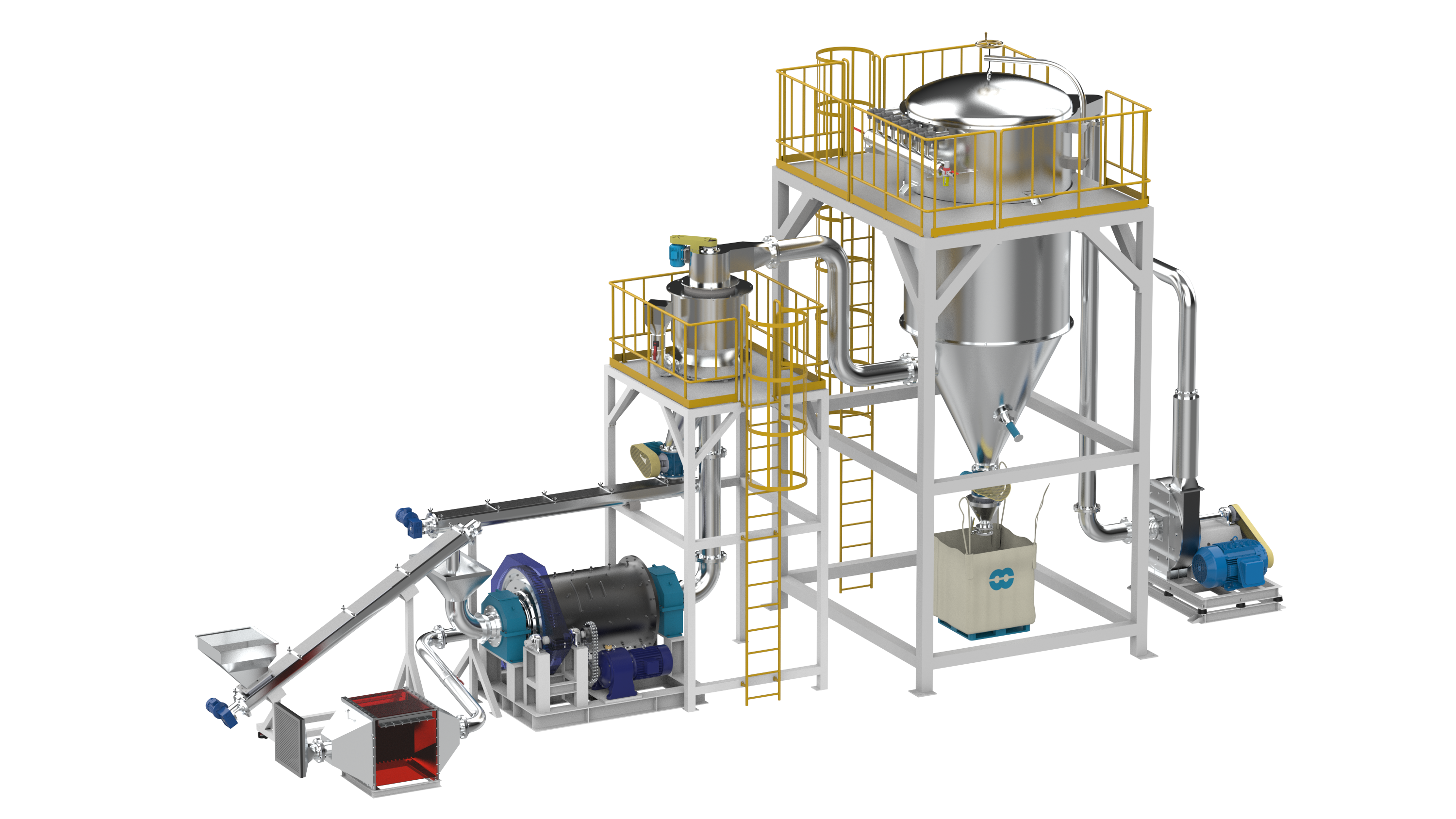

Mineral Drying & Milling & Separating System

Main Text

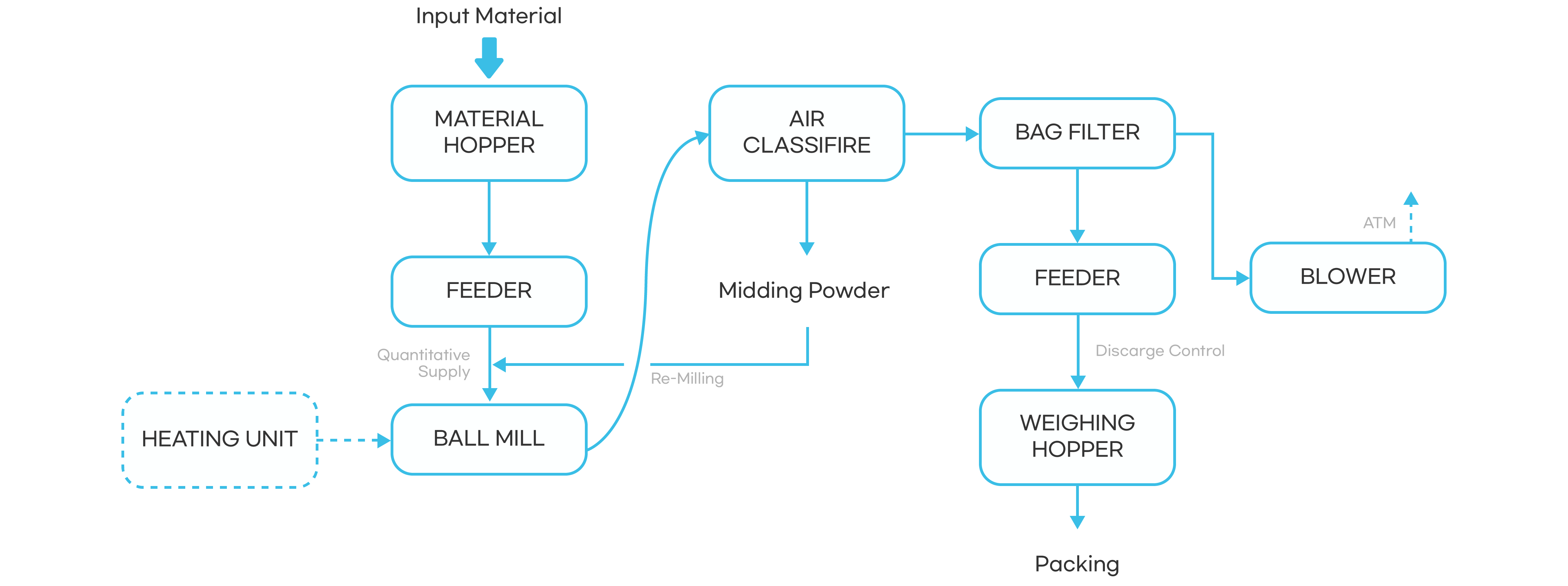

System Flow

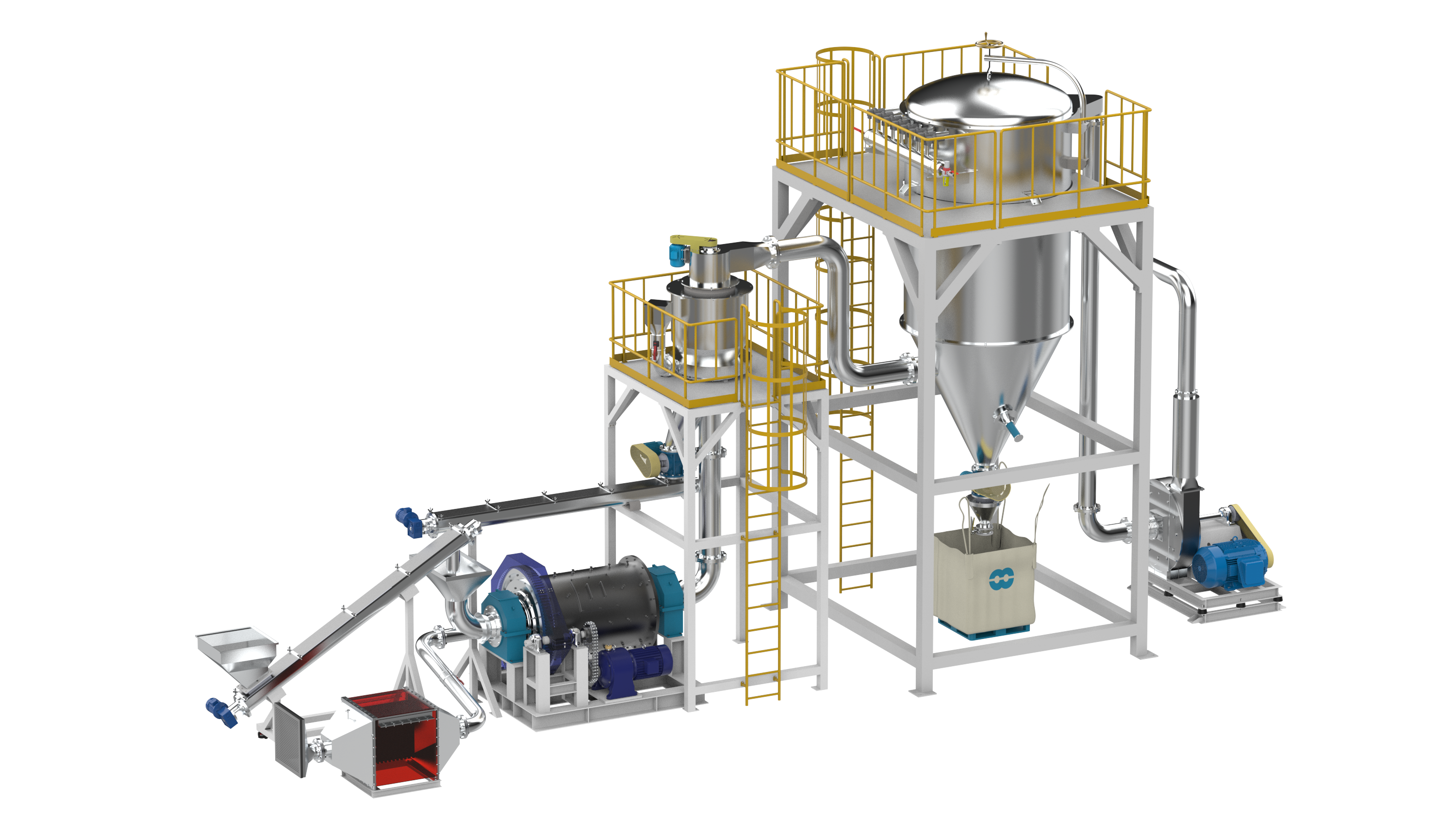

Installation Image

Characteristics

By performing drying and milling simultaneously, the system efficiently reduces energy consumption.

The system allows for continuous air classification during the milling process, enabling particle size control.

The milling device applies centrifugal force to the grinding media, which generates impact force, frictional force, and shearing force to achieve milling.

Various types of media can be used, including Balls (ceramic, stainless steel, iron) and Rods (steel).

The system can be configured as a continuous or batch type and is capable of operating in a closed circuit.

Application

Ideal for producing fine particles in industries such as cement, ceramics, and chemicals.

Suitable for the production of fine particles from various types of minerals.

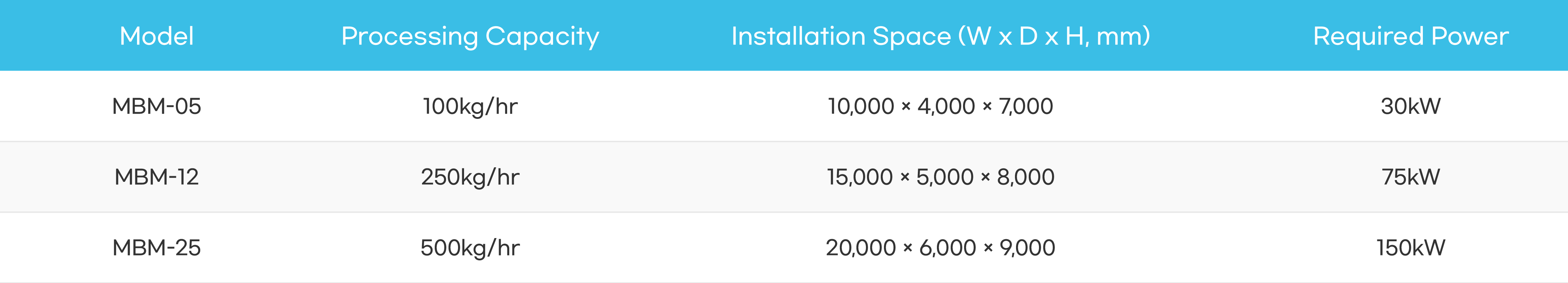

Dimension

- Previous PostClassification Jet Mill System Using Inert Gas 24.08.23

Comments List

No comments have been registered.