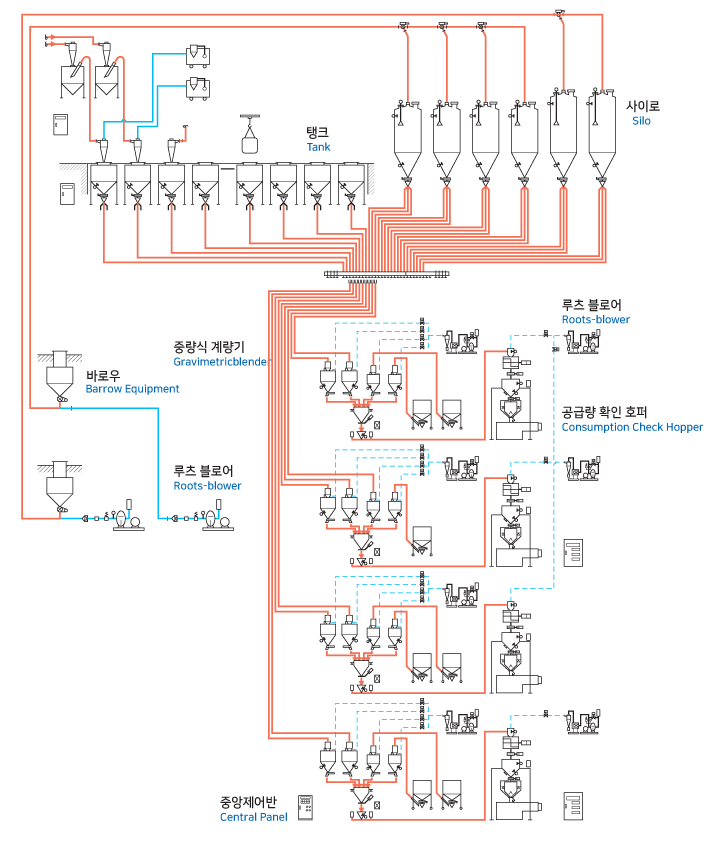

An example of a system that mixes multiple materials into four multi-layer extruders

A commonly used main material is introduced from a tank trolley or bulk bag and supplied to an outdoor silo.

Sub-materials such as additives are put in bulk bags, and collected and pulverized materials are temporarily stored in an indoor tank from the grinder.

For materials in the outdoor silo and indoor tank, replenishment timing is notified by level gauges.

Each material is selected for each extruder used by the connection stand.

In addition, sub-materials that are less used are supplied from a small amount of material tank installed on the side of the mixing device.

The gravimetric mixing device integrates and measures four types of materials on one scale.

The measured batch of mixing materials is supplied to the mixer at the top of the extruder,

and the load cell monitoring the supply amount is placed and supplied to the upper hopper of the extruder.