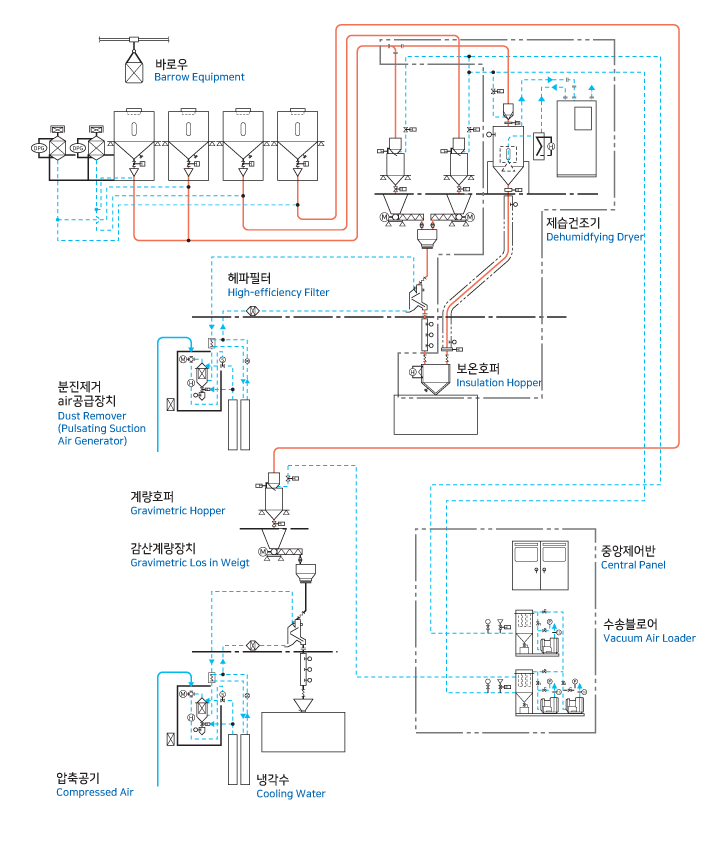

An example of a material supply system with optical specifications in consideration of contamination prevention throughout the flow

Material is input from the bulk bag to the optical specification tank.

Weight management using a load cell is adopted in accordance with the management of the material in the tank.

Clean air that has passed through a HEPA filter is utilized as the secondary air used for air transport to the mixing device.

The two materials supplied to the main extruder are mixed by loss-in metering, passed through a HEPA filter, and fed into a warmed extrusion hopper.

Materials dried in the dehumidifying dryer supplied to the same main extruder pass through the warming chute and are supplied to the warming extrusion hopper.

Materials supplied to the sub-extruder is supplied to the load cell attached hopper that monitors the supply amount,

and the material continuously measured by subtractive weighing passes through the HEPA filter and is supplied to the extruder.